| RISOGRAPH孔版印刷與一般彩色雷射噴墨或是UV印刷不同

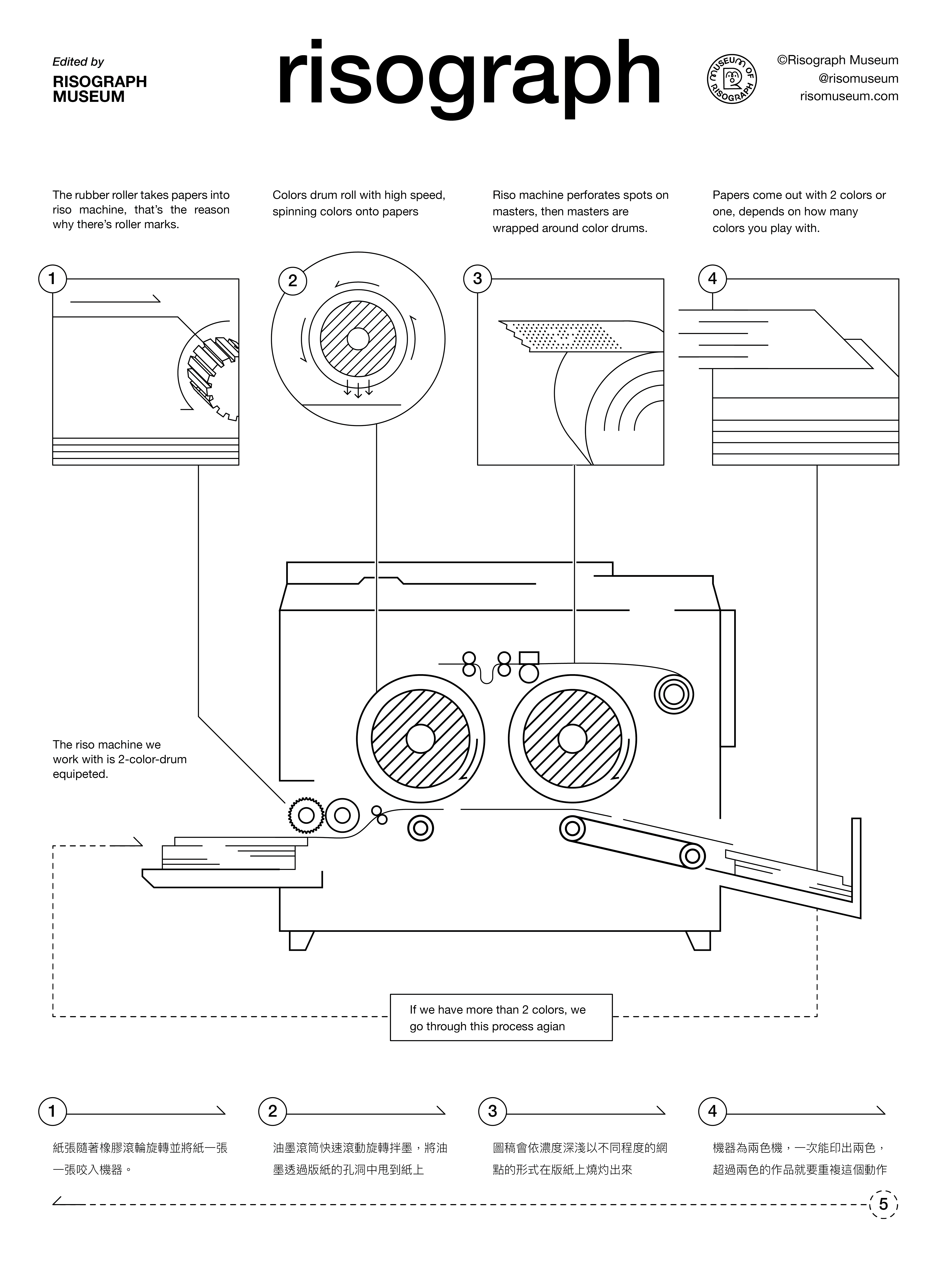

RISO印刷的過程是在機器內部形成一個模板,此模板附著在充滿油墨的滾筒上,隨著滾筒高速運轉迫使油墨透過模板附著在紙上,是一種類似絹印、版畫的印刷方式。 一般目前最普及的四色印刷,是以青、桃紅、黃與黑即CMYK疊出各種顏色;而RISOGRAPH孔版印刷則提供了非常多種油墨顏色選擇,包含了許多普通印刷沒有的螢光色,當然還有很受歡迎的金色,本店目前有23色,也將持續新增。 孔版印刷毋需像一般印刷廠的特殊色需要印刷大量才能壓低單價,因此相對少量的特殊色出版物一直是RISO的強項。 「如果你要印超過五十份,但是又少於一萬份的出版物,那RISOGRAPH印刷會是最經濟,並且亮麗的選擇」其實這就是這台機器被發明的初衷,所以它在日本曾經紅極一時,每間學校,小印刷店幾乎都會備有一台 囊括了許多海內外前輩與我們自己的經驗,我們覺得Risograph印刷最迷人的地方,除了亮麗的色彩以外,最有趣的還是他有點任性與不確定性的小脾氣,偶爾反而能給創作者意外的驚喜。 |

Risograph printing is exclusively spot color based, which is similar to screen printing and printmaking. Unlike digital printing, there is no option to print in standard color like CMYK. Riso provides a wide variety of ink color options, including many fluorescent colors which are not available in ordinary printing. Metallic gold is very popular especially in Asia. Of course, we have it. We now have 23 different colors, and will continue to add more. In addition, Risograph printing does not require a large amount of special colors to lower the price. Therefore, a relatively small number of special colors has always been a superiority of Risograph printing. The original marketing principal is actually quite straightforward:If you need to make more than 50 but fewer than 10,000 prints of something, it’s cheaper to do it with a Riso. We think that the charm of risograph printing, except the bright color, is its unpredictable and capricious character. Which brings you unexpacted surprises. |

RISOGRAPH 特色

|

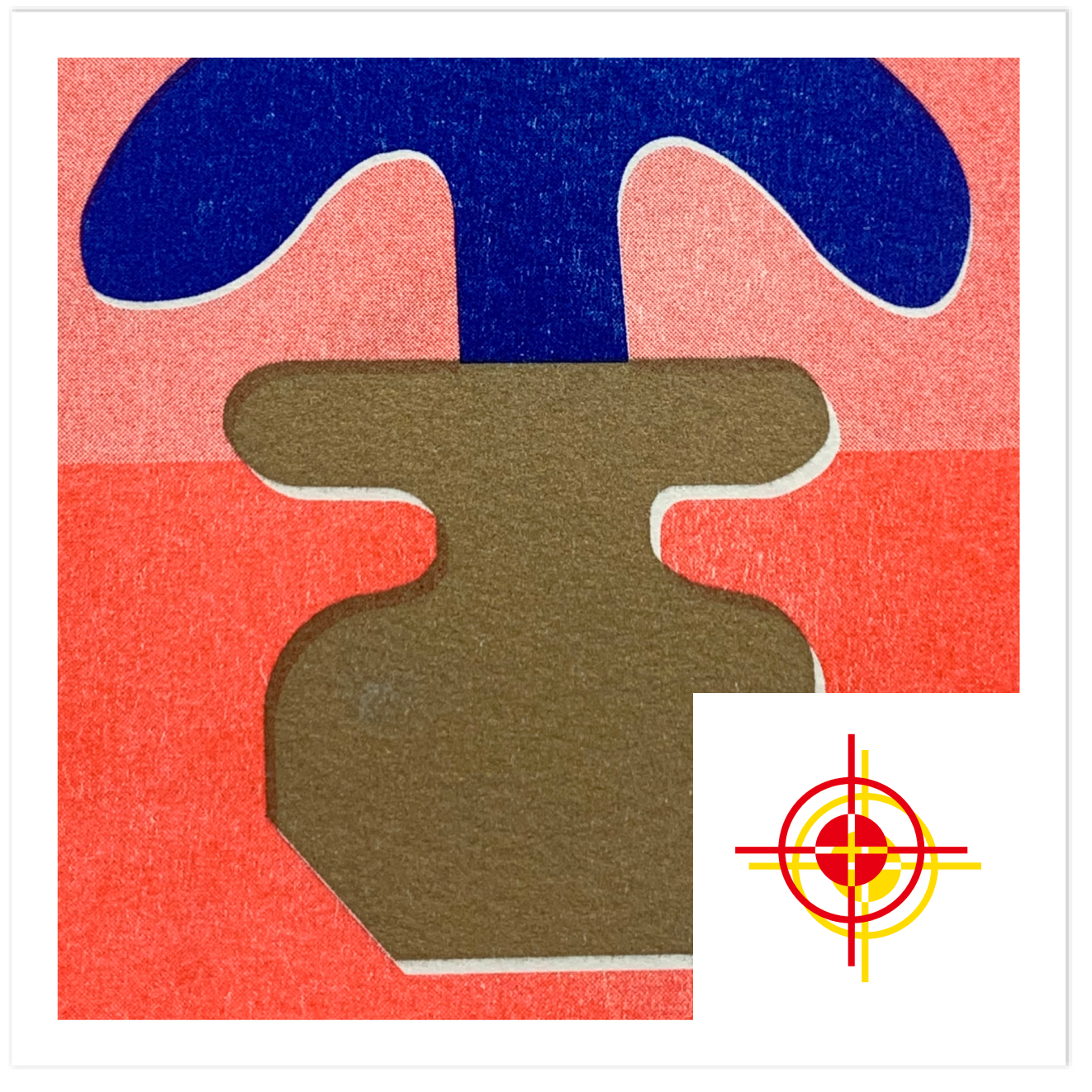

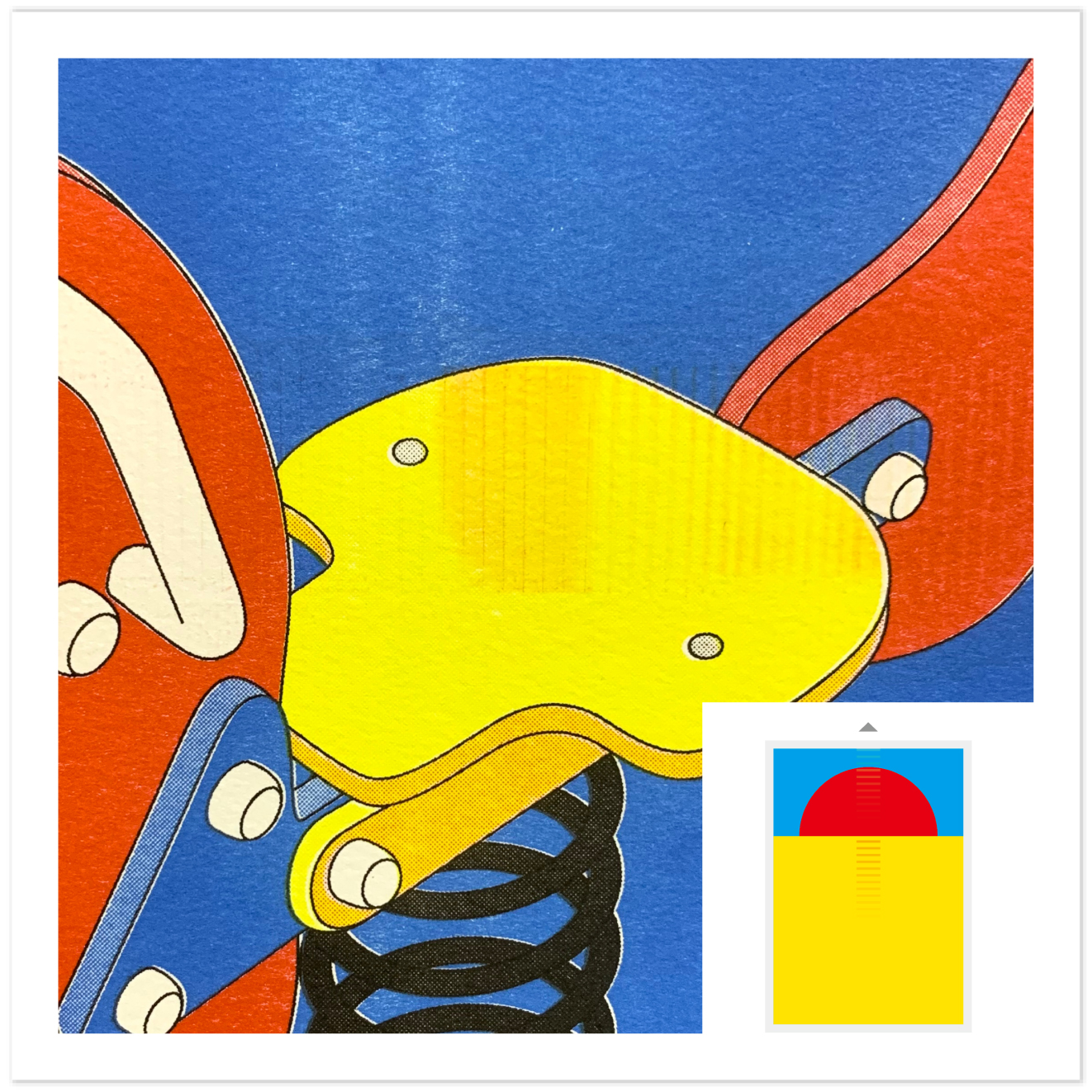

錯位 Misregistration

孔版印刷必定會有些微的錯位,每一張印刷品不可能都完全一致。孔版印刷機器一次只能印製兩色,每個顏色都需要手動對位,因此如果需要非常精準的印刷品,則需要慎重考慮是否要選擇Risograph印刷。不過其實錯位這種不確定因素造成的每一張都有點不相圖的獨特性,反而是很多人選擇孔版印刷的原因呢。

Every 2 color layer is printed individually, so colours rarely line up perfectly on top of each other. This gives Riso’s distinctive misregistration an unavoidable part of the process. This is an inherent part of the process that makes each print totally unique. If you are open to imperfections and experimental result, Risograph printing will be perfect for you! |

|

摩擦掉色&大面積墨色不均 Smudging

Riso ink is made of soy or rice oil. Which is environmentally-friendly. This type of ink stays open many hours after printing and will smudge if enough pressureIs applied to it. |

|

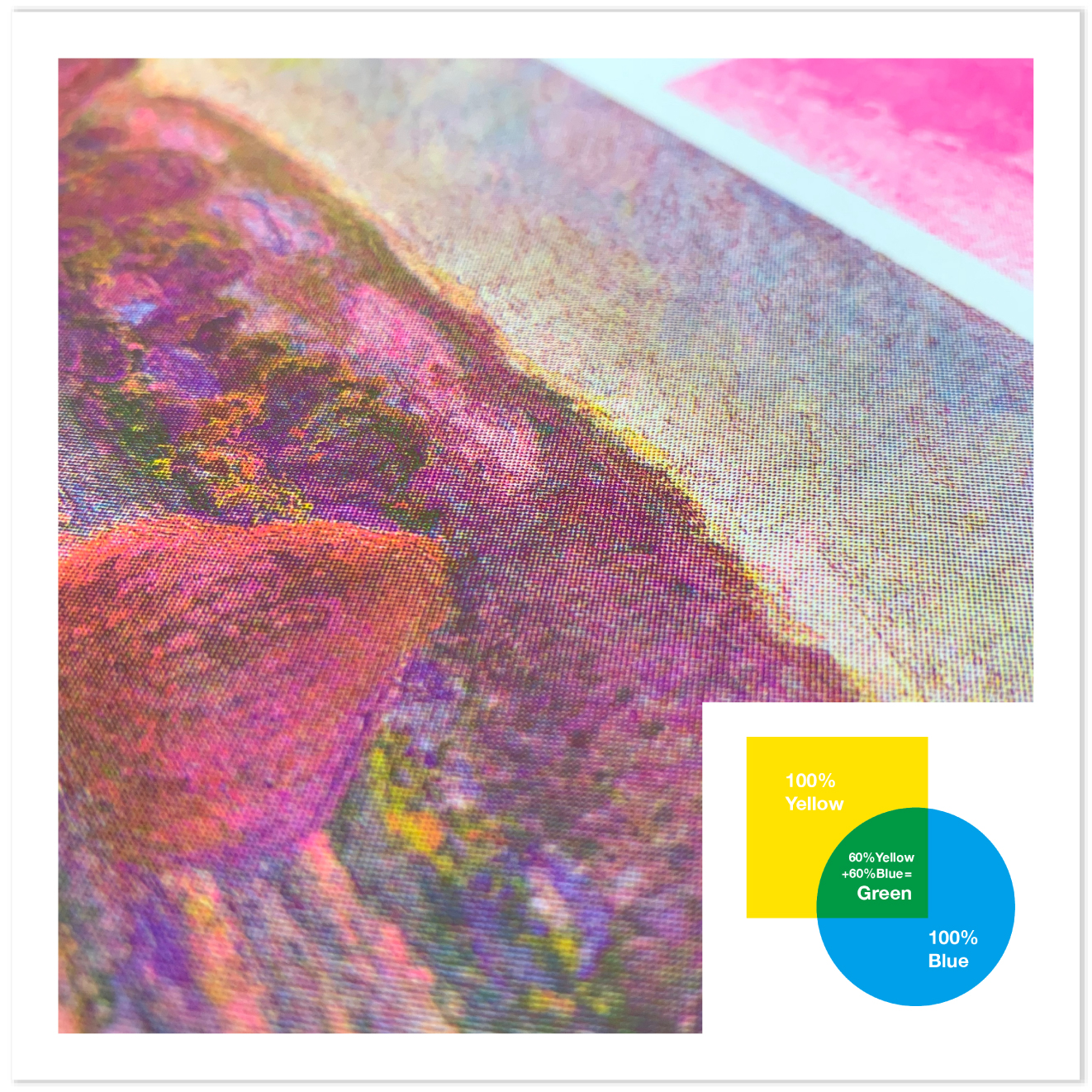

混色 Color Overlapping

多色印刷時會因印刷順序產生不同效果,工作人員會依成果最好的順序去印製,建議混色時可以先跟工作人員討論,或是先試印確認效果後再進行調整或大量印製。 With colors overlapping, it's fun to have surprising results. Like all we know that overlapping yellow and blue would produce green. And yet with different density or different yellow and blue, you can have variety of green. For instance, we have 3 kinds of yellow and 4 kinds of blue, how many tone of green would you probably get? |

|

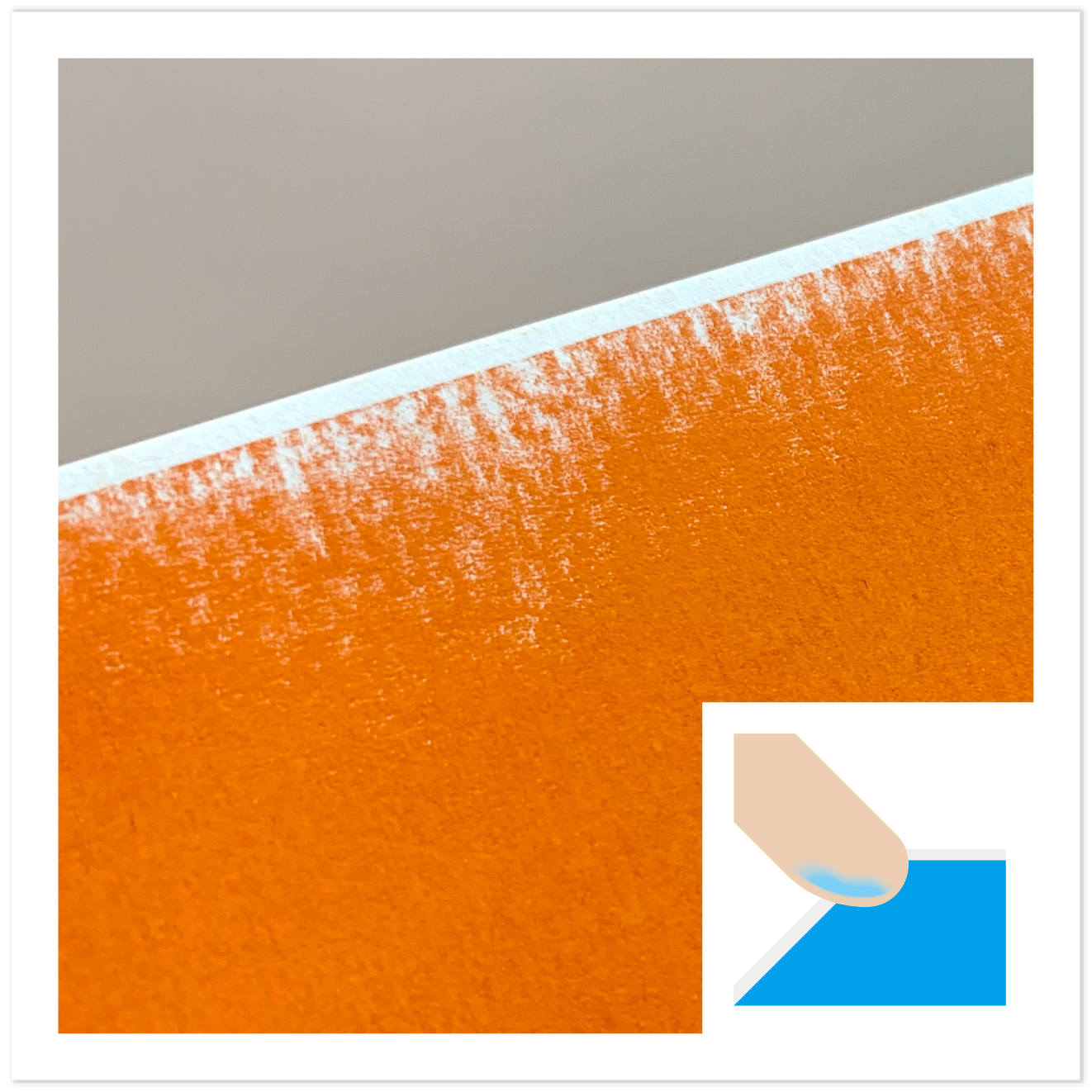

色塊&水痕 Uneven Coverage

基本上所有墨色都會出現色塊問題,但深色的墨色會較為嚴重。 Sometimes, there will be some uneven coverage of colors appear on prints. This situation happens especially if you print with high color intensity and large area. |

|

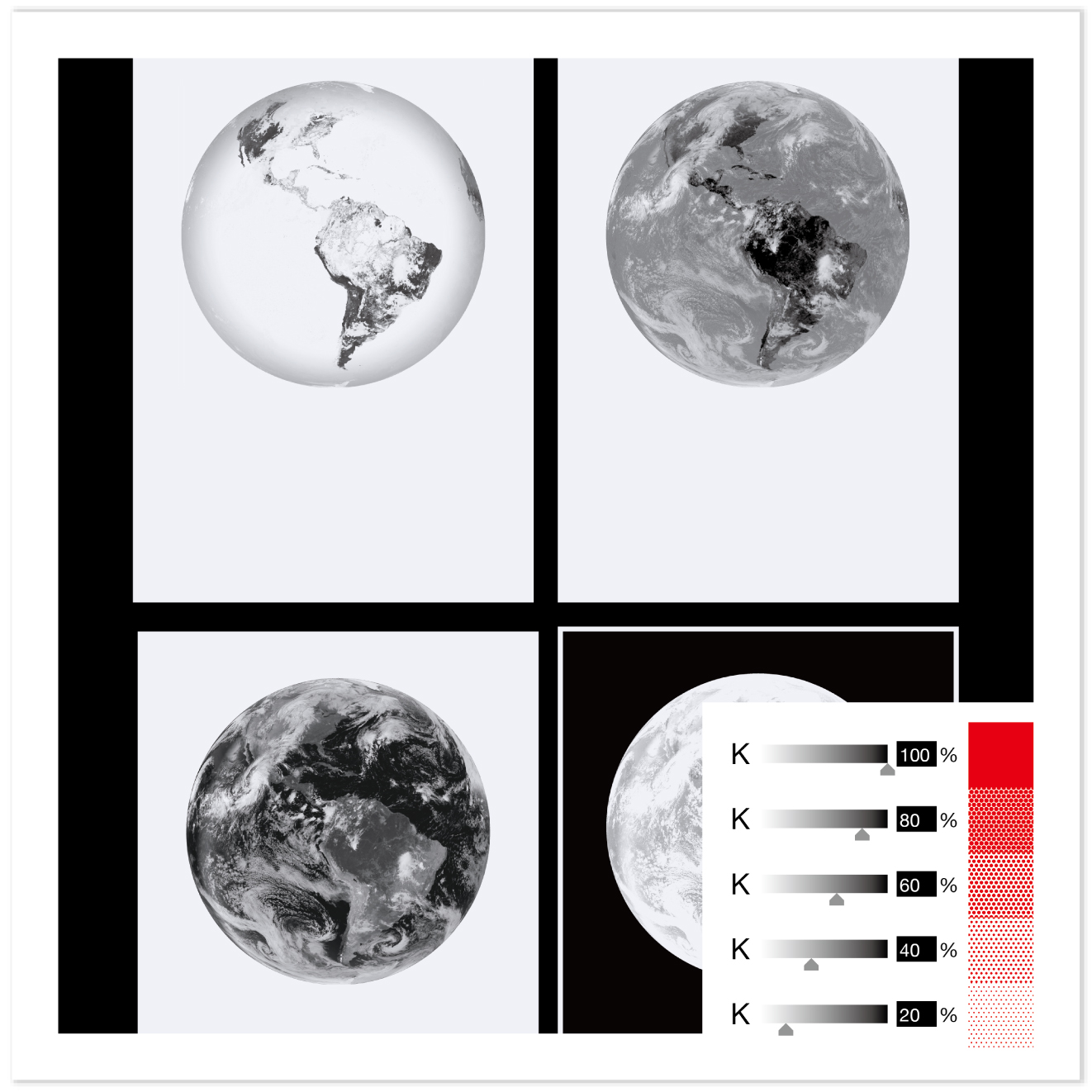

黑白稿入檔並選擇顏色

如右圖以是以黑白入檔,並選擇印刷成紅色,黑色的濃度即會決定顏色的濃度。 強烈建議黑白入稿時CMY皆為0,調整K的數值即可,詳細示意圖請見「原稿製作教學頁」(示意圖並非印刷效果)。 The file for the Risograph must contain only grayscale information and will be transformed into halftones automatically by the RIso. Each file can contain different gray values. 100% black in each color layer, will print out as 100% of whichever color you are printing. 60% black will print as 60% and so on.

|

|

滾輪印 Roller Marks

紙張是通過滾輪送到印刷機進行印製,由於油墨特性不會立即乾燥,油墨容易附著在滾輪上。調整印製程序及擦拭滾輪可以減輕滾輪印,但如果印刷是大面積圖形或者是色版中間有高濃度油墨時,滾輪痕跡則無法避免。 Paper is fed through the Risograph with a rubber wheel. This applies pressure to ink, which can leave a mark on your artwork. For artwork with heavy ink coverage, roller marks may occur in the area shown in this graphic aside. |

|

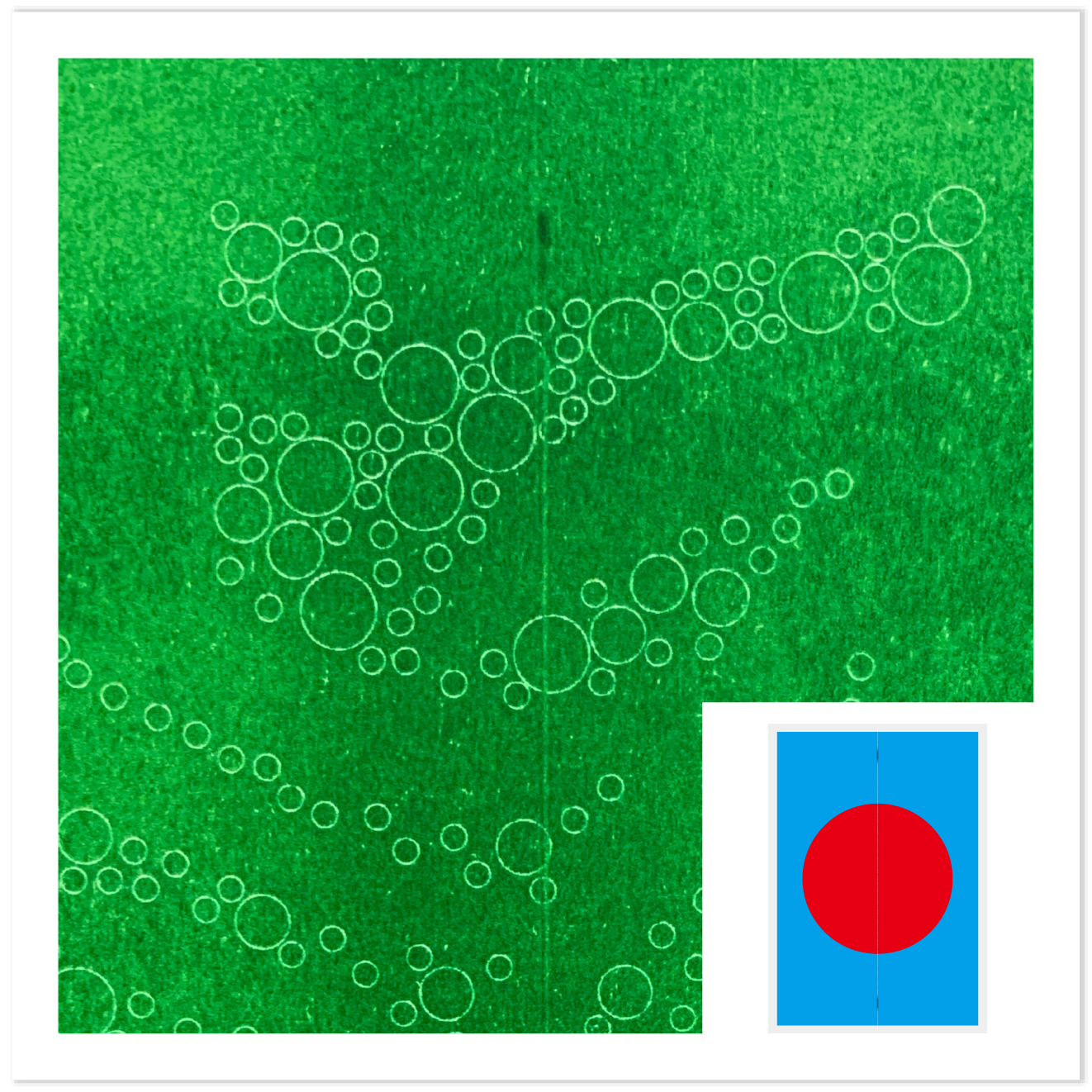

針跡 Pin Marks

若油墨用色範圍較大且濃,紙張容易沾黏在滾筒的版紙上,為了能順利送紙,孔版印機內的「細針」會將濕黏的紙張脫離滾筒,而針所劃過的一條線痕則稱為針跡。 建議若較為介意,可以減少油墨的使用面積或降低油墨濃度。 Paper is fed through the Risograph with a rubber wheel. This applies pressure to ink, which can leave a mark on your artwork. For artwork with heavy ink coverage, roller marks may occur in the area shown in this graphic aside. |

|

墨跡 Ink Marks

版紙附著在油墨滾筒上,因此本身的紋路與產生的曲折就是產生墨跡的原因之一,尤其為濃度高且面積大的稿件在印刷時容易有高機率出現像水波般的墨痕,而深色的墨色較為嚴重。 雖然出現的機率難以預期,但減少色塊面積能夠降低產生墨痕的風險。 Paper is fed through the Risograph with a rubber wheel. This applies pressure to ink, which can leave a mark on your artwork. For artwork with heavy ink coverage, roller marks may occur in the area shown in this graphic aside. |

|

雙面印刷壓痕 Stress Marks

當雙面印刷時,其中一面用色面積較大,進紙時機器會摩擦到以印製的圖稿,導致下張紙印刷時邊緣會沾染到油墨。 Paper is fed through the Risograph with a rubber wheel. This applies pressure to ink, which can leave a mark on your artwork. For artwork with heavy ink coverage, roller marks may occur in the area shown in this graphic aside. |

|

紙背邊緣破損 Broken of Paper

多色印刷以及紙張磅數較高等等,在印刷機送紙時容易磨損紙張,造成產生紙張背後邊緣破損。 Paper is fed through the Risograph with a rubber wheel. This applies pressure to ink, which can leave a mark on your artwork. For artwork with heavy ink coverage, roller marks may occur in the area shown in this graphic aside. |

|

RISOGRAPH PRININTING,孔版印刷

1946年 羽山昇 於東京成立了一間蠟紙印刷店 在他發明了第一台Risograph孔版印刷機後 這家小小的印刷店在1963年正式更名為RISO KAGAKU工業株式會社 羽山昇會如此命名是有其意義的 在日語中「RISO」是理想的意思,而「KAGAKU」則是科學 所以這家公司也可稱作「理想科學」工業株式會社 |

Noboru Hayama, the Inventor of the Risograph machine, started his business in 1946.

He established a mimeograph printing company in Tokyo, Japan. After Mr.Hayama invented the first RISO printer duplicator, this printing store changed the name of the company to “Riso Kagaku Corporation”. In Japanese speaking, “Riso”means “ideal” and “Kagaku” means “science”. |